Vacuum thermoforming

Who needs vacuum thermoforming and why?

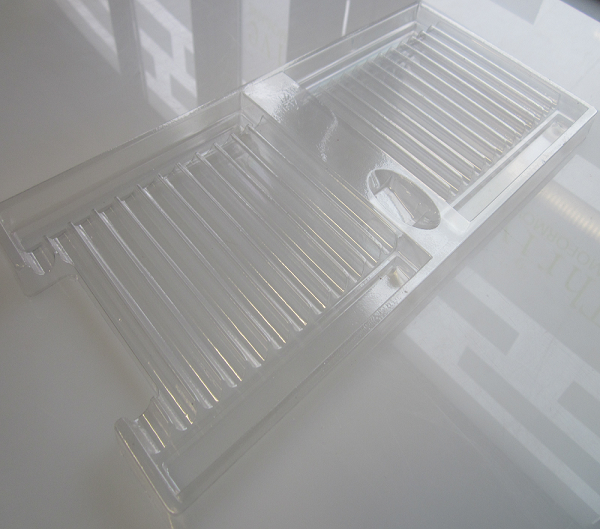

I would like to explain it in a quite simple way. Vacuum thermoforming is a packaging method which requires heat and vacuum. Whatever shape you need, we can create it basing on these two factors.

If we take a closer look at this method, we can divide it into three stages:

heating the sheet until it starts to melt,

putting the heated sheet on the form,

creating vacuum in the form.

In the final stage we put the sheet either inside or outside the form – it depends on the project and method.

Let me give you a practical example – a prototype. Thermoforming is a perfect solution if you need to present a single prototype (i.e. for investors or customers). Production costs will be lower than in comparison to other possible methods (i.e. injection molding).

You should consider thermoforming if you need:

grocery packages,

packages for cosmetics or household chemicals,

non-standard products of bigger size – i.e. outdoor advertisements like outdoor signs or advertising coffers.

How it looks?

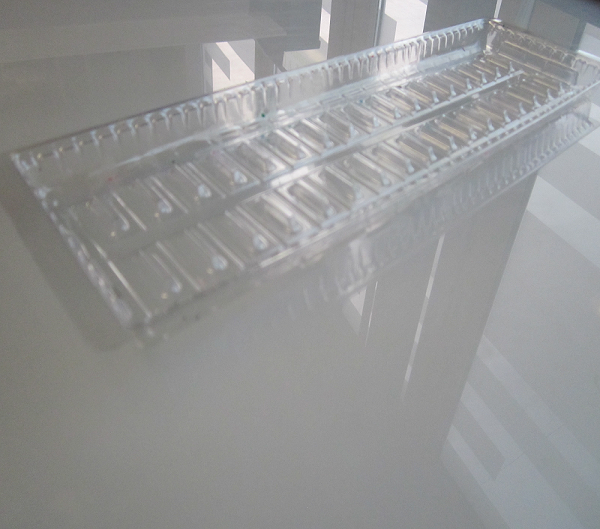

Our job starts with developing the form for your product.

Take an example of our customer who wants to pack certain amount of coloured pencils.

First, they have to deliver these crayons to us, so that we can prepare a proper form.

We prepare this form especially for this product – considering its dimensions and properties of its material.

When the form is ready, we pass it to the client for their approval. We advise them to give us feedback, especially If they have doubts or questions. If their remarks are vital for the production process, we take them into consideration and make all the necessary improvements. If we disagree with them – we propose another solution. The advisory part of our job is done when the customer approves the form.

How long does it take to create a form? Usually up to 30 days.

From this moment the production process starts.

Our services